Supreme Info About What Type Of Wires Can Be Joined Using The In-sure Lever Wire Connector

Unlocking the Secrets of In-Sure Lever Wire Connectors

1. Understanding the Versatility of Lever Wire Connectors

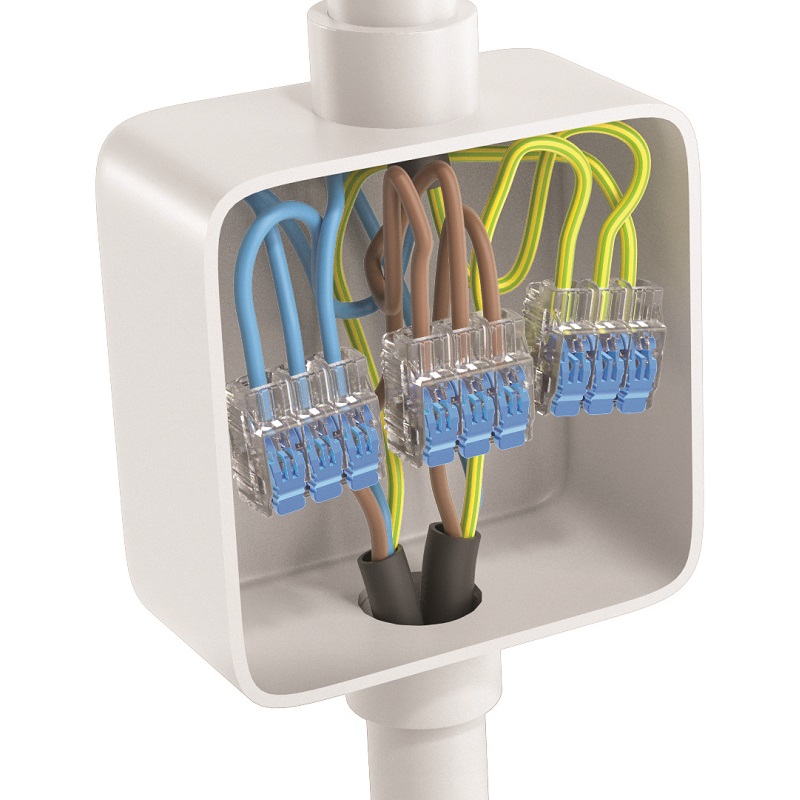

So, you're staring at a pile of wires and an In-Sure lever wire connector, huh? Wondering if these little gadgets are the right tool for the job? You're not alone! Choosing the right connector is essential for a safe and reliable electrical connection. The good news is, In-Sure connectors are pretty versatile, but like any superhero, they have their limits. Let's dive in and figure out what kind of wires these connectors can handle.

First off, let's establish some ground rules. In-Sure connectors are generally designed for solid and stranded copper wires. That's your standard Romex wiring you find in most homes. Aluminum wiring? That's a different ballgame altogether. Mixing copper and aluminum can lead to corrosion and fire hazards, so you'll need specialized connectors designed explicitly for that purpose. Always check the manufacturer's specifications on the package — they're there for a reason! Ignoring them is like trying to assemble furniture without the instructions... chaos will ensue.

Think of it this way: solid wire is like a rigid, disciplined soldier standing at attention. Stranded wire is more like a team of flexible acrobats, bending and adapting as needed. In-Sure connectors embrace both types, allowing for a secure connection regardless of the wire's composition. But, and this is a big but, pay attention to the wire gauge. Each connector is designed for a specific range of wire sizes, usually indicated in AWG (American Wire Gauge). Trying to cram a too-thick or too-thin wire into the connector is a recipe for disaster. You'll either damage the connector or create a loose, unreliable connection. No bueno!

Imagine attempting to insert a size 12 foot into a size 9 shoe — it just won't work, no matter how much you wiggle! It's the same principle with wire connectors. Respect the gauge range, and the connector will reward you with a secure and lasting connection. And remember, when in doubt, consult a qualified electrician. They're the experts, and they can guide you through any wiring conundrum you might encounter. Electricity is a serious matter, so don't take chances!

Lever Wire Connectors T Type Quick Wiring Terminal Block Connecotr

Solid vs. Stranded

2. Delving Deeper into Wire Types

Alright, let's get a bit more specific. Solid core wire, as the name suggests, is a single, solid piece of copper. It's typically used for residential wiring because it's easier to run through walls and ceilings. Think of it as the backbone of your home's electrical system. In-Sure connectors grip solid wires with a firm and unwavering hold, creating a reliable connection that won't easily come loose.

Stranded wire, on the other hand, is made up of multiple thin strands of copper twisted together. This makes it more flexible and resistant to breakage, perfect for applications where the wire needs to bend and move. Think of the wires in your lamp cord or extension cord. Stranded wire is more forgiving when it comes to flexing and movement, making it ideal for projects that require a little give-and-take.

The beauty of In-Sure connectors is that they can handle both solid and stranded wire with equal ease. The internal mechanism is designed to grip the wire securely, regardless of its composition. This makes them a versatile choice for a wide range of electrical projects. Just make sure you strip the wires to the correct length before inserting them into the connector. Too much insulation left on the wire, and you won't get a good connection. Too little, and you risk exposing the bare wire, which can be a safety hazard.

And here's a pro tip: when working with stranded wire, give the strands a little twist before inserting them into the connector. This will keep them from fraying and ensure a more secure grip. It's like giving the wire a little pep talk before sending it into battle. A well-prepared wire is a happy wire! Ultimately, the key is to pay attention to the details and follow the manufacturer's instructions. With a little care and attention, you can create a safe and reliable electrical connection every time.

Ideal Gen II Lever Wire Connector 3 Ports (Box Of 40) 300093 At TEW

Gauge Expectations

3. The Importance of Wire Gauge Compatibility

Now, let's talk about wire gauge — the thickness of the wire. It's usually measured in AWG (American Wire Gauge), and the smaller the number, the thicker the wire. For example, 12 AWG wire is thicker than 14 AWG wire. This is crucial because different electrical circuits require different wire gauges to handle the load. A circuit powering a toaster oven, for instance, will need a thicker wire than a circuit powering a lamp. In-Sure connectors are designed to work with a specific range of wire gauges, so you need to make sure you're using the right connector for the job.

Using the wrong gauge wire can be dangerous. If the wire is too thin, it can overheat and potentially cause a fire. If it's too thick, it might not fit properly into the connector, leading to a loose and unreliable connection. It's like trying to fit a square peg into a round hole — it's just not going to work! Always check the manufacturer's specifications on the In-Sure connector to see what wire gauges it's designed to handle. This information is usually printed right on the connector itself.

Think of wire gauge as the size of a pipe. A small pipe can only handle a small amount of water, while a large pipe can handle a lot more. Similarly, a thin wire can only handle a small amount of electricity, while a thick wire can handle a lot more. Matching the wire gauge to the circuit's requirements is essential for safety and performance. And remember, when in doubt, it's always better to err on the side of caution. If you're unsure about the correct wire gauge, consult a qualified electrician.

In addition to gauge, the type of wire is important. Solid wires are frequently used for residential electrical wiring. Stranded wires are often used for extension cords, appliances and other things requiring flexibility. Most In-Sure connectors are designed for both stranded and solid core wires. But always make sure the In-Sure lever wire connector is fully seated to prevent loose connections and other potentially dangerous issues.

Aluminum Wiring

4. Addressing Aluminum Wiring Compatibility

Okay, this is important. We've talked about copper wires, but what about aluminum wiring? Aluminum wiring was used in some homes built in the 1960s and 1970s, and it's known to be more prone to corrosion and overheating than copper wiring. The important point to remember is that standard In-Sure lever wire connectors are generally NOT suitable for aluminum wiring. Connecting copper wire directly to aluminum wire can cause corrosion due to galvanic action, which can lead to loose connections and fire hazards. So, unless the connector is specifically designed and rated for aluminum wiring, avoid using it. This is a critical safety consideration!

If your home has aluminum wiring, you'll need to use special connectors that are designed to bridge the gap between copper and aluminum. These connectors are often filled with a special compound that prevents corrosion and ensures a safe and reliable connection. Using the wrong type of connector on aluminum wiring can be extremely dangerous, so don't take any chances. Look for connectors that are specifically labeled for use with aluminum wiring, and follow the manufacturer's instructions carefully. These connectors often include antioxidant compounds to prevent corrosion from occurring.

Think of it as trying to mix oil and water — they just don't play well together. Copper and aluminum are similar in that regard. They require a special intermediary to get along. Using the wrong connector is like trying to force them to mix, and it's likely to end in disaster. A qualified electrician can inspect your wiring and recommend the best solution for your specific situation. They can also perform the necessary repairs or upgrades to ensure that your electrical system is safe and up to code.

Working with aluminum wiring requires specialized knowledge and expertise. If you suspect that your home has aluminum wiring, it's best to call in a professional electrician to assess the situation and recommend the appropriate course of action. Don't attempt to DIY electrical work unless you're fully qualified and experienced. Electricity is a force to be reckoned with, and it's always better to err on the side of safety. Your family's safety is worth the investment in professional electrical services. If you plan on installing it on your own, cut off the electricity first.

GKEEMARS DIN Terminal Blocks Universal Wiring Connector Lever

In-Sure Connectors

5. Recap and Best Practices for Usage

Let's recap, shall we? In-Sure lever wire connectors are fantastic tools for connecting solid and stranded copper wires, provided you use the right connector for the job. Make sure the wire gauge matches the connector's specifications, and never use standard In-Sure connectors on aluminum wiring. Always follow the manufacturer's instructions, and when in doubt, consult a qualified electrician. And hey, before you start any electrical work, always turn off the power at the circuit breaker. Safety first!

Think of In-Sure connectors as the building blocks of your electrical system. When used correctly, they provide a secure and reliable connection that will last for years to come. But like any tool, they need to be used with care and attention to detail. Make sure the wires are stripped to the correct length, and insert them fully into the connector until they click into place. A good connection is a secure connection, and a secure connection is a safe connection.

So, there you have it! A comprehensive guide to using In-Sure lever wire connectors. With a little knowledge and a healthy dose of caution, you can tackle your electrical projects with confidence. Just remember to always prioritize safety, and never hesitate to seek professional help when needed. With these connectors, it's possible to create a secure connection that minimizes the risk of electrical shock, overheating, and other potential hazards.

And one last tip: before you close up the electrical box, give the wires a gentle tug to make sure they're securely connected. It's like giving them a little test to see if they're up to the task. If a wire comes loose, it's a sign that you need to re-seat it or use a different connector. Taking the time to double-check your work can save you a lot of headaches down the road. Now go forth and conquer those wiring projects, armed with your newfound knowledge of In-Sure lever wire connectors!