What Everybody Ought To Know About What Is NPN Sinking

Understanding NPN Sinking

1. What Exactly is NPN Sinking?

So, you've stumbled upon the term "NPN sinking" and you're probably thinking, "What in the world does that even mean?" Don't worry, you're not alone! It sounds a bit technical, but the core concept is pretty straightforward, especially if you've dabbled in electronics or automation. Think of it this way: NPN sinking is simply a method of controlling electronic circuits, like a specific type of light switch, but for industrial applications. It's all about how current flows and how devices communicate.

Essentially, an NPN sinking output means that the device "sinks" current to ground (negative terminal) when it's active or "on." Imagine a drain in your sink — when the drain is open, water flows into it. Similarly, with NPN sinking, current flows into the output terminal when the device is activated. It's like the device is providing a path for the current to flow to ground. This contrasts with other methods where the device would source current (push it out), which we'll touch on later.

This method is commonly used in programmable logic controllers (PLCs) and other industrial control systems. Why? Because it's a robust and reliable way to interface with various sensors and actuators. Think of it as a common language spoken by machines. The "language" is the current flow, and the NPN sinking method provides a standard way for devices to "talk" to each other.

To picture it clearly, imagine a simple circuit where you have a sensor connected to a PLC input. The sensor needs to signal the PLC when it detects something (let's say an object). With NPN sinking, when the sensor detects the object, it closes the circuit, allowing current to flow from the PLC input, through the sensor, and into the sensor's output terminal (which is sinking to ground). The PLC then recognizes this current flow as a signal that the object has been detected.

What Is A Sinking Output? Vs. Sourcing Explained RealPars

The Nuts and Bolts

2. Digging Deeper into the Mechanism

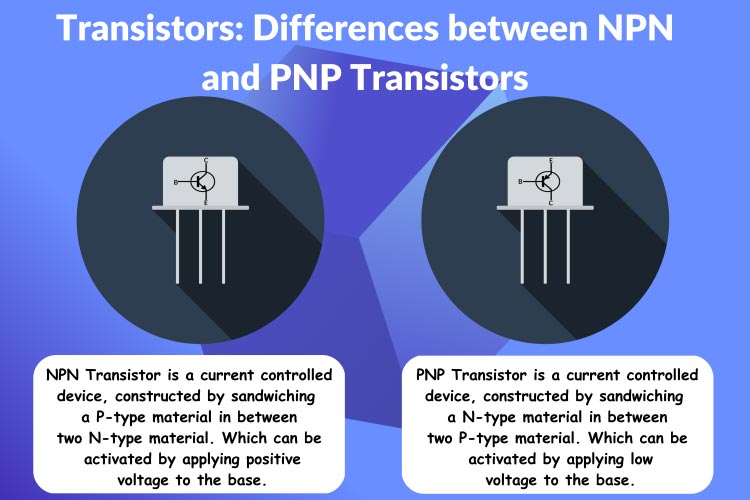

Alright, let's get a little more specific about the "how." Under the hood, NPN sinking relies on NPN transistors. These transistors act like electronically controlled switches. When the transistor is turned "on" (by a signal from the control system), it creates a low-resistance path to ground, allowing current to flow through the load (the device being controlled) and then through the transistor to ground. It's like opening a gate to let the electrical current pass through.

The beauty of using transistors is that they can switch very quickly and reliably. This is crucial in industrial applications where precise timing and consistent performance are paramount. Think of a conveyor belt in a factory; the sensors and actuators need to respond instantaneously to ensure everything runs smoothly. NPN sinking, with its fast-switching transistors, helps to make that happen.

Now, let's talk about the voltage levels. In most NPN sinking circuits, the "off" state is near the supply voltage, and the "on" state is near zero volts (ground). This clear distinction makes it easy for the control system to determine the state of the device. It's a simple yes/no, on/off signal. No ambiguity, no confusion, just clear communication.

But remember, the devil is in the details. You need to ensure that the voltage and current ratings of the transistors and other components are appropriate for the application. Overloading the components can lead to overheating, damage, and system failure. Always consult the manufacturer's specifications and follow proper wiring practices. It's like baking a cake; you need the right ingredients in the right proportions!

NPN Sinking vs. PNP Sourcing

3. Choosing the Right Method for Your Application

So, NPN sinking is one option, but there's also its counterpart: PNP sourcing. What's the difference, and why does it matter? In short, PNP sourcing is the opposite of NPN sinking. Instead of "sinking" current to ground when active, a PNP sourcing device "sources" current from the positive supply when active. It's like the device is pushing current out, rather than pulling it in.

The choice between NPN sinking and PNP sourcing often depends on the specific application and the wiring conventions used in the control system. In some regions, NPN sinking is more common, while in others, PNP sourcing is preferred. It's like the difference between driving on the left side of the road versus the right; it's mostly a matter of convention and what you're used to.

Generally, NPN sinking is considered more robust in environments with potential for electrical noise. The reason is that if a wire were to accidentally short to ground, it would simply activate the output, which is a safer condition than a short causing an unintended activation with a PNP sourcing output. It's like a fail-safe mechanism. However, PNP sourcing can be easier to troubleshoot in some cases, as the positive voltage is easier to trace.

Ultimately, the best approach is to understand the pros and cons of each method and choose the one that best suits your needs. Consider factors such as the type of sensors and actuators you're using, the wiring conventions in your region, and the level of electrical noise in the environment. And when in doubt, consult with an experienced engineer or technician. They can provide valuable guidance and help you avoid costly mistakes.

Practical Applications

4. Real-World Examples of NPN Sinking

Now that we've covered the theory, let's look at some real-world examples of where you'll find NPN sinking in action. As mentioned earlier, it's commonly used in industrial automation, but the applications are far more diverse than you might think. From controlling robotic arms to monitoring water levels, NPN sinking plays a crucial role in countless processes.

One common application is in machine safety systems. For example, emergency stop buttons often use NPN sinking outputs to signal the PLC when the button is pressed. When the button is pressed, it opens the circuit, stopping the current flow to the PLC input. This signals the PLC to immediately shut down the machine, preventing potential accidents. It's a critical safety feature that relies on the reliability of NPN sinking.

Another application is in process control. Imagine a chemical plant where the level of a liquid needs to be constantly monitored. Level sensors with NPN sinking outputs can be used to signal the PLC when the liquid level reaches a certain point. The PLC can then take appropriate action, such as opening a valve to drain the tank or stopping the flow of liquid into the tank. This ensures that the process stays within safe and optimal limits.

You'll also find NPN sinking in packaging machinery, conveyor systems, and even automated car washes. In fact, any application that requires reliable and precise control of electrical signals is likely to use NPN sinking or its counterpart, PNP sourcing. It's the unsung hero of the industrial world, quietly working behind the scenes to keep things running smoothly. So next time you see a robot arm welding a car body or a conveyor belt moving boxes, remember that NPN sinking may be playing a part!

Troubleshooting Tips

5. Diagnosing and Resolving Common Issues

Even with the best planning and execution, things can sometimes go wrong. So, what do you do when your NPN sinking circuit isn't working as expected? Don't panic! With a systematic approach and a little bit of detective work, you can usually track down the problem and get things back on track. Think of yourself as an electrical Sherlock Holmes, solving the mystery of the malfunctioning circuit.

First, check the basics. Make sure that the power supply is working correctly and that all the connections are secure. Loose wires and faulty power supplies are common culprits. A multimeter is your best friend here; use it to measure voltages and check for continuity. It's like a stethoscope for your electrical circuits!

Next, check the sensors and actuators. Are they functioning properly? Are they wired correctly? Sometimes, a sensor can fail or a wire can become disconnected. Again, a multimeter can be used to test the sensors and actuators. Also, check the wiring diagrams to ensure that everything is connected as it should be.

If you've checked the basics and the problem persists, it may be a more complex issue. In this case, you may need to consult with an experienced engineer or technician. They can use advanced troubleshooting techniques and equipment to diagnose the problem. They can also help you identify potential design flaws or wiring errors. Remember, safety first! Always disconnect the power before working on electrical circuits.

Animation What Is Sinking And Sourcing In PLC SOURCE /SINK / PNP

FAQs About NPN Sinking

6. Your Burning Questions Answered

Still scratching your head? Here are some frequently asked questions to clarify any remaining points:

Q: Is NPN sinking the same as "open collector"?

A: Yes, the terms are often used interchangeably. An open collector output is essentially the same thing as an NPN sinking output. It refers to the fact that the collector of the NPN transistor is left "open," allowing it to sink current to ground when activated.

Q: Can I mix NPN sinking and PNP sourcing devices in the same system?

A: While technically possible, it's generally not recommended unless you're absolutely sure of what you're doing and have taken appropriate precautions. Mixing different output types can lead to wiring errors and compatibility issues. It's generally best to stick to one output type throughout the system to avoid confusion and ensure proper operation.

Q: What happens if I accidentally short an NPN sinking output to the positive supply?

A: Shorting an NPN sinking output to the positive supply can damage the output transistor. It's like overloading a circuit; the transistor may overheat and burn out. To prevent this, always use appropriate overcurrent protection devices, such as fuses or circuit breakers.