Painstaking Lessons Of Info About What Is DC Vs PLC

Plc Digital Input And Output Modules Instrumentation Vrogue.co

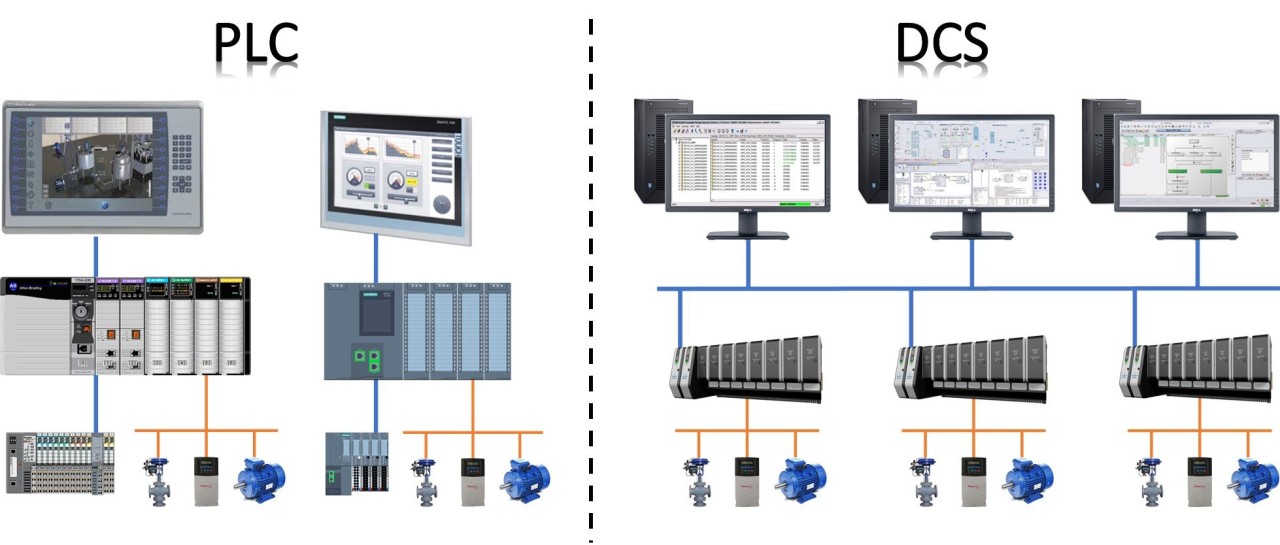

DC vs. PLC

1. Understanding the Basics

Ever found yourself scratching your head, wondering what the difference is between DC and PLC? It's like trying to decipher a secret electrical code! Don't worry; you're not alone. These terms are foundational in the world of electronics and automation, but they often get mixed up. Let's break it down in a way that's easier to digest than that last plate of nachos.

Direct Current (DC), as the name suggests, flows in one direction. Think of it like a one-way street for electrons. Batteries, solar panels, and those adorable little USB chargers all deliver DC power. It's consistent, predictable, and generally well-behaved. If electricity were a movie star, DC would be the reliable, leading man type.

Now, let's talk Programmable Logic Controllers (PLCs). A PLC is essentially a specialized computer used to control industrial processes. Imagine it as the brain of a manufacturing plant, orchestrating everything from conveyor belts to robotic arms. It takes in information from sensors, makes decisions based on pre-programmed logic, and then sends out signals to control actuators, which do the actual work. It's the conductor of the industrial orchestra, ensuring everything plays in harmony.

So, the initial confusion often arises because PLCs require DC power to operate. They're sophisticated devices packed with electronics, and most of that electronics runs on DC voltage. It's like your brain needing oxygen — the PLC needs DC to function!

The Key Differences

2. Delving Deeper

The main difference boils down to their roles. DC is a type of electrical power, while a PLC is a control system. Think of it this way: DC is the fuel, and the PLC is the car. You can't drive a car without fuel, and you can't run a PLC without DC power. It's a symbiotic relationship, a power duo working together to make awesome things happen.

DC power is characterized by its constant voltage and current direction. This makes it ideal for powering sensitive electronic components. You wouldn't want alternating current (AC) surging through your phone's charging circuit, would you? That would be a recipe for electronic disaster!

On the other hand, a PLC's strength lies in its ability to automate complex tasks. It uses a programming language (often ladder logic, which resembles electrical schematics) to define its behavior. This allows engineers to easily modify and adapt the PLC's control strategy without having to rewire entire systems. Imagine trying to reprogram a factory line using relays and timers alone — you'd be there all day (and probably the next day, too!).

The PLC gathers info via input modules that connect to things like sensors. Based on the program it runs, it then tells outputs what to do. These outputs connect to physical stuff like motors and actuators. Picture a robot arm painting a car — the PLC is orchestrating every move.

What Is The Difference Between PLC And DCS? RealPars

Why Both Are Important

3. Synergy in Action

Understanding both DC and PLCs is crucial in many industries, especially manufacturing, automation, and robotics. They're often used together to create efficient and reliable control systems. Without DC power, the PLC is just a fancy paperweight. Without the PLC, DC power is just, well, power, without a defined purpose.

Imagine a bottling plant. DC power supplies the PLC, which then controls the entire filling, capping, and labeling process. The PLC monitors sensors to ensure the bottles are filled correctly, adjusts the conveyor speed, and even detects potential problems, like a bottle that's not properly sealed. Its a symphony of coordinated actions, all powered by DC and orchestrated by the PLC.

Consider an automated warehouse. DC powers the PLCs that control the robotic arms, conveyor belts, and sorting systems. The PLC's programming dictates how packages are routed, stored, and retrieved, ensuring that orders are fulfilled accurately and efficiently. It's like a giant game of Tetris, but with boxes instead of blocks, and the PLC is the master player.

In essence, DC provides the energy, and the PLC provides the intelligence. They work hand-in-hand to create systems that are more efficient, reliable, and adaptable than ever before. They're the dynamic duo of the industrial world, constantly pushing the boundaries of what's possible.

Practical Applications

4. Real-World Examples

You'll encounter DC and PLCs in a surprisingly wide range of applications. Think of the renewable energy sector, where solar panels generate DC power. This DC power is often used to charge batteries, which in turn can power PLCs that control energy storage and distribution systems. It's a clean, efficient way to manage energy resources.

In the automotive industry, PLCs are used extensively in assembly lines to control robots, welding machines, and painting systems. DC power supplies the PLCs, ensuring that these critical systems operate reliably and consistently. From the initial stamping of the chassis to the final application of the paint, PLCs are involved in every step of the manufacturing process.

Even in your own home, you're likely surrounded by devices that rely on DC power and are indirectly controlled by PLCs. For example, the control systems for heating, ventilation, and air conditioning (HVAC) systems often incorporate PLCs to optimize energy efficiency and maintain comfortable temperatures. And, of course, all those electronic gadgets you love are powered by DC.

Looking ahead, the integration of DC and PLCs is only going to become more prevalent. As industries continue to automate and embrace the Internet of Things (IoT), the need for reliable and intelligent control systems will only increase. This means that understanding the fundamentals of DC and PLCs will be an invaluable skill for anyone working in engineering, technology, or manufacturing.

Difference Between PLC And DCS

Troubleshooting and Maintenance

5. Keeping Things Running Smoothly

Let's face it, things break down. Even the most sophisticated systems aren't immune to the occasional hiccup. When it comes to troubleshooting systems that use DC power and PLCs, a systematic approach is key. First, check the power supply. Is the DC voltage within the specified range? A multimeter is your best friend here.

Next, examine the PLC's inputs and outputs. Are the sensors sending the correct signals? Are the actuators responding as expected? PLC programming software often includes diagnostic tools that can help you pinpoint the source of the problem. It's like having a built-in detective to solve your automation mysteries.

Regular maintenance is also crucial. Keep the PLC's enclosure clean and free of dust and debris. Check the wiring for loose connections or damaged insulation. Periodically back up the PLC's program to prevent data loss in case of a hardware failure. Think of it as giving your industrial brain a regular check-up.

When troubleshooting, don't forget safety! Always disconnect the power before working on any electrical equipment. Follow proper lockout/tagout procedures to prevent accidental energization. Electricity is powerful, but it's also unforgiving. Safety should always be your top priority.

Difference Between PLC And DCS Systems

Frequently Asked Questions (FAQs)

6. Your Burning Questions Answered

Q: Can I use AC power to directly power a PLC?

A: Generally, no. PLCs typically require DC power. You'll need a power supply to convert AC voltage to the appropriate DC voltage for the PLC.

Q: What is ladder logic?

A: Ladder logic is a programming language commonly used for PLCs. It resembles electrical schematics, making it easier for electricians and technicians to understand and program the PLC.

Q: Are PLCs only used in large factories?

A: Not at all! While they're common in large industrial settings, PLCs are also used in smaller applications, such as controlling traffic lights, elevators, and even some home automation systems.

Q: What are the advantages of using a PLC compared to traditional relay-based control systems?

A: PLCs are more flexible, easier to reprogram, and more reliable than relay-based systems. They also offer advanced features like data logging, remote monitoring, and communication capabilities.