Awe-Inspiring Examples Of Info About How Do You Measure Torque

How To Solve Torque

Unlocking the Mystery

Ever wondered how engineers figure out how much twisting power an engine, a motor, or even your own two hands can generate? That's where torque measurement comes in! Torque, at its core, is a rotational force. Think of it as the "oomph" that makes things spin. Understanding how to measure torque is essential in everything from designing cars to building bridges, and even ensuring your bike's wheels are on tight.

The part of speech for "torque" here is a noun. This is crucial because our discussion centers on understanding and quantifying this specific physical concept.

Measuring torque accurately isn't just about satisfying curiosity; it's about safety, efficiency, and ensuring things work the way they're supposed to. Imagine a poorly designed bridge where the torque on a bolt wasn't properly calculated — yikes! So, let's dive into the methods and tools used to measure this crucial rotational force. This journey might even inspire you to consider a career in engineering! Okay, maybe not, but it's still pretty interesting stuff.

Think of torque as the twisting force that makes things rotate. It's not just about how fast something spins (that's angular velocity), but how hard it's spinning. A powerful engine has high torque, meaning it can apply a lot of twisting force, even at low speeds. It's the difference between a hummingbird fluttering its wings incredibly fast and a grizzly bear lumbering forward with immense power. Both are forces, but very different in how they are exerted. Ready to understand more?

1. Understanding the Basics of Torque

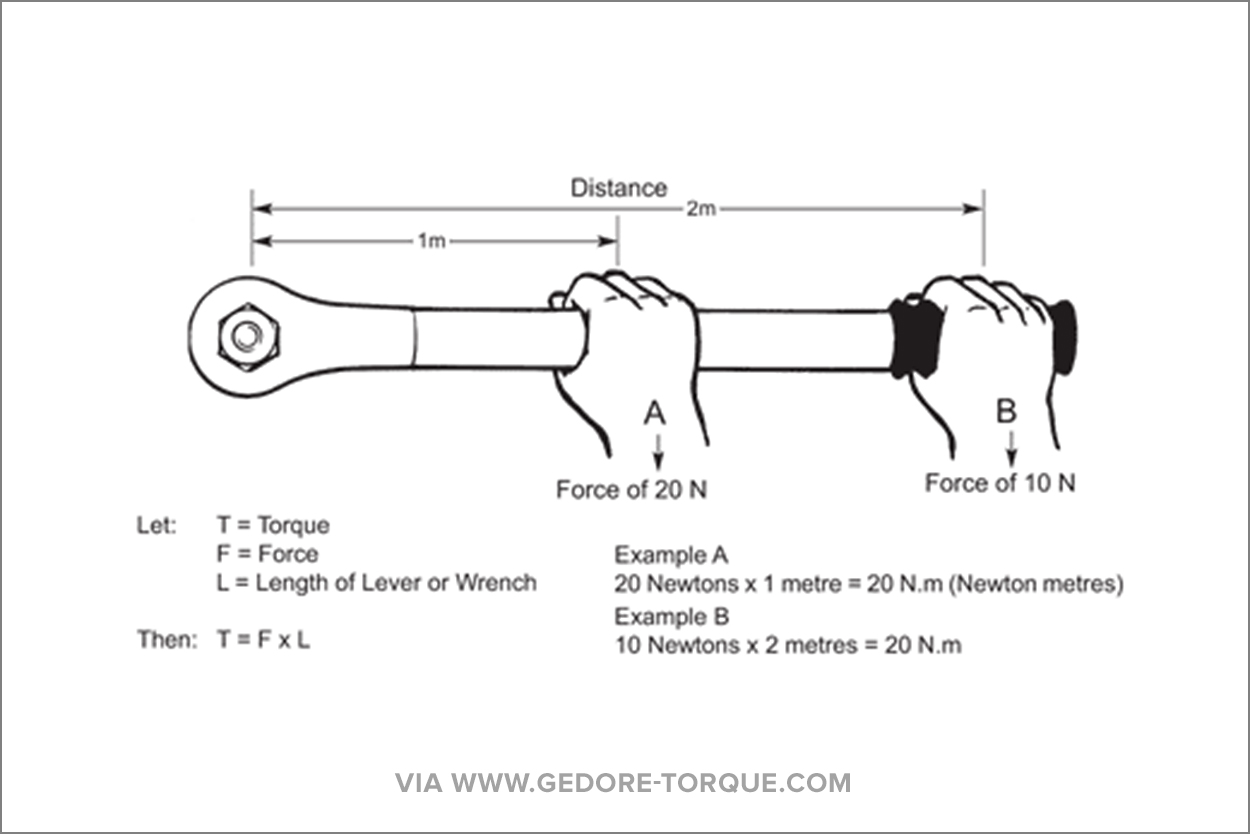

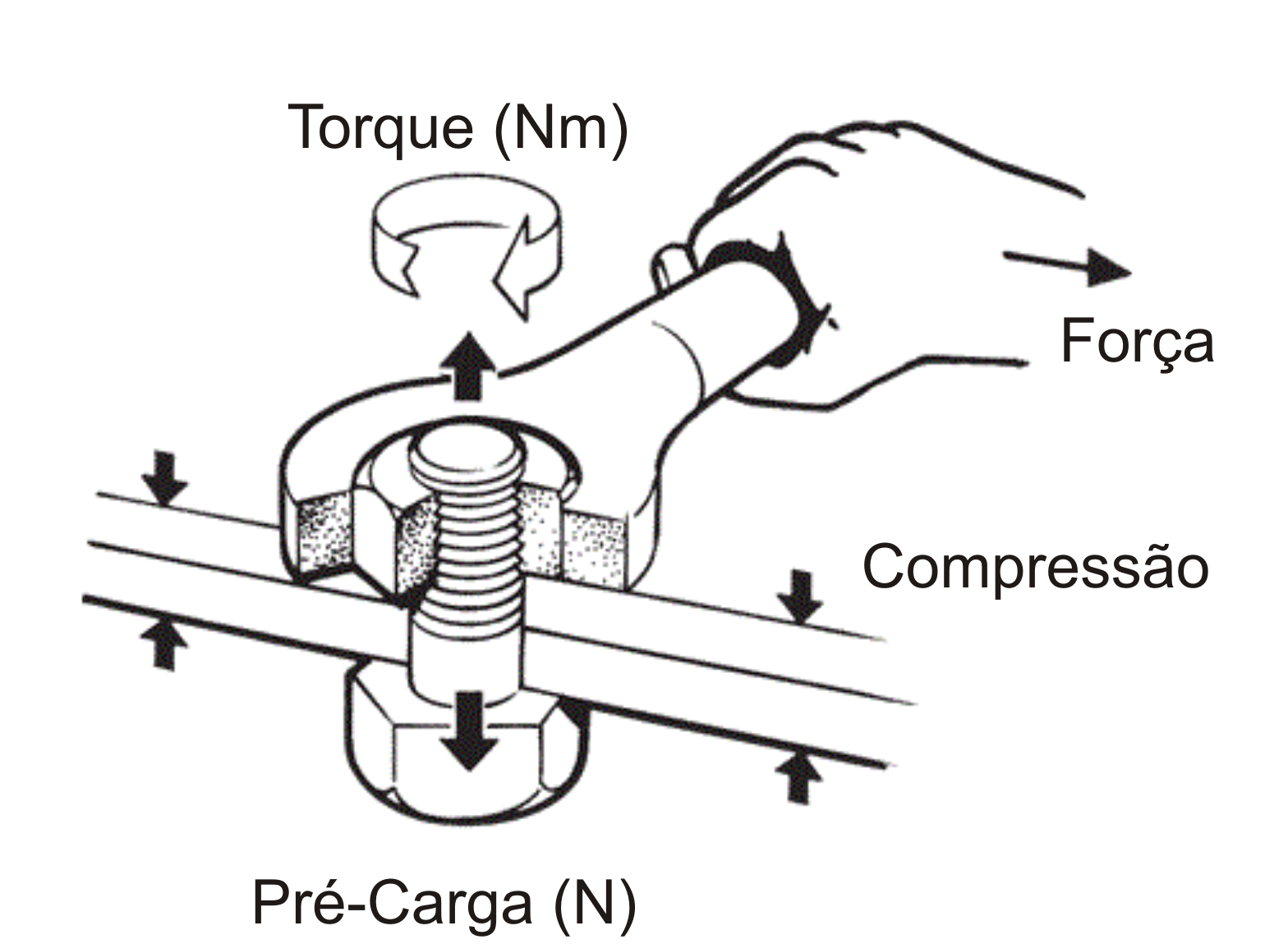

Before we jump into the measurement methods, let's solidify our understanding of what torque actually is. Torque is defined as the force that causes an object to rotate about an axis. It's the product of the force applied and the distance from the axis of rotation to the point where the force is applied. That distance is often called the "moment arm."

So, if you're using a wrench to tighten a bolt, the force you apply to the wrench handle, multiplied by the length of the wrench, gives you the torque on the bolt. A longer wrench gives you more leverage — more torque for the same amount of force. Makes sense, right? It's like giving your muscles a mechanical advantage!

The standard unit of measurement for torque is Newton-meters (Nm) in the metric system and pound-feet (lb-ft) in the imperial system. These units tell you how much twisting force is being applied. So, when you see a car advertised with "300 lb-ft of torque," that means the engine can generate a twisting force of 300 pounds at a distance of one foot from the center of rotation.

Its important to remember that torque isn't just a static measurement. It can change over time, especially in dynamic systems like engines. Measuring dynamic torque is often more complex and requires specialized equipment, which we'll get into later. This is where things can get a little hairy, but don't worry, we'll keep it simple!

(PDF) Basics Of Torque Measuring English DOKUMEN.TIPS

Different Tools for Different Twists

Alright, let's get to the good stuff: how do you actually measure torque? There are several methods, each suited to different applications and levels of precision. We'll cover some of the most common ones, from simple hand tools to sophisticated electronic sensors.

2. Manual Torque Wrenches

The simplest way to measure torque is with a manual torque wrench. These wrenches are designed to apply a specific amount of torque to a fastener, like a bolt or nut. They come in various types, but the most common are beam-type, click-type, and dial-type wrenches.

Beam-type torque wrenches are the simplest and most affordable. They have a beam that deflects under load, and a scale that indicates the amount of torque being applied. While reliable, they require a direct visual reading, which can be tricky in tight spaces or when applying high torque.

Click-type torque wrenches are more precise and user-friendly. You set the desired torque value, and when that value is reached, the wrench "clicks," indicating that you've applied the correct amount of torque. These are great for repetitive tasks and are less prone to reading errors.

Dial-type torque wrenches feature a dial gauge that displays the torque being applied. They offer high accuracy and are often used in more critical applications. Theyre also pretty cool to watch in action!

3. Electronic Torque Sensors

For more precise and automated torque measurement, electronic torque sensors are the way to go. These sensors use strain gauges to measure the deformation of a shaft under torque. The strain gauges convert the deformation into an electrical signal, which is then processed and displayed as a torque value.

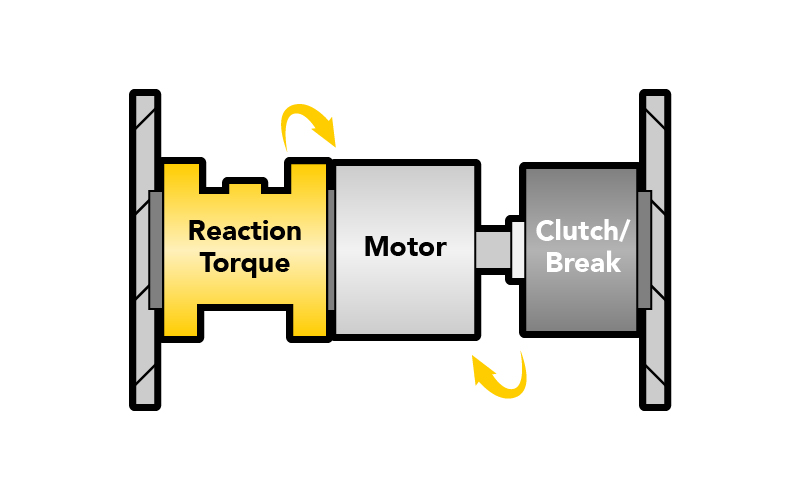

Electronic torque sensors come in various forms, including rotary torque sensors, reaction torque sensors, and torque transducers. Rotary torque sensors are used to measure the torque of rotating shafts, such as those in engines or motors. Reaction torque sensors measure the torque that is resisting rotation, such as the torque on a fixed component. Torque transducers are general-purpose sensors that can be used in a wide range of applications.

These sensors are often integrated into testing equipment and automated systems. They provide real-time torque data, which can be used for process control, quality assurance, and research and development. Imagine being able to see exactly how much force a robot arm is exerting thats the power of electronic torque sensors!

One of the benefits of electronic torque sensors is their ability to measure dynamic torque. This is essential for understanding the performance of engines, transmissions, and other rotating equipment. Dynamic torque measurements can reveal valuable information about vibrations, imbalances, and other factors that can affect performance and reliability.

O Que é A Medida Nm De Torque?

Factors Affecting Torque Measurement Accuracy

Measuring torque accurately is crucial, but several factors can affect the accuracy of your measurements. Let's take a look at some of the most important ones to ensure you're getting reliable results.

4. Calibration

Like any precision instrument, torque wrenches and sensors need to be calibrated regularly. Calibration ensures that the tool is providing accurate readings by comparing its output to a known standard. Over time, torque wrenches can drift out of calibration due to wear and tear, so regular calibration is essential for maintaining accuracy.

Most torque wrench manufacturers recommend calibrating your wrench at least once a year, or more frequently if it's used heavily. Calibration services are available from specialized companies that use certified equipment to verify and adjust the wrench's accuracy. Think of it as a yearly check-up for your torque wrench, making sure it's still in tip-top shape!

Electronic torque sensors also require calibration. The calibration process typically involves applying known torques to the sensor and adjusting the sensor's output to match the known values. Regular calibration ensures that the sensor is providing accurate and reliable data. It's like tuning a musical instrument; you want to make sure it's playing the right notes!

Failure to calibrate your torque measuring devices can lead to inaccurate readings, which can have serious consequences. Imagine over-tightening a bolt on an airplane engine because your torque wrench is out of calibration — not a scenario you want to be in!

5. Environmental Conditions

Environmental conditions can also affect the accuracy of torque measurements. Temperature, humidity, and vibration can all influence the performance of torque wrenches and sensors. For example, temperature changes can cause the materials in a torque wrench to expand or contract, which can affect its accuracy.

Humidity can also affect torque measurements by causing corrosion or oxidation of the wrench's components. Vibration can introduce noise into the measurements, making it difficult to obtain accurate readings. To minimize the effects of environmental conditions, it's important to use torque measuring tools in a controlled environment whenever possible.

When working in harsh environments, it's also important to choose torque measuring tools that are designed to withstand those conditions. For example, some torque wrenches are made from corrosion-resistant materials, and some electronic torque sensors are designed to be vibration-resistant. This ensures that the tool remains accurate and reliable, even in challenging conditions.

Think of it like this: you wouldn't wear a delicate silk dress to a mud wrestling match, would you? Similarly, you need to choose the right torque measuring tool for the environment you're working in.

6. Proper Technique

Even with the best tools and calibration, proper technique is essential for accurate torque measurement. Applying torque incorrectly can lead to inaccurate readings and even damage to the tool or the fastener.

When using a torque wrench, it's important to apply the force smoothly and evenly. Avoid jerking or snapping the wrench, as this can cause inaccurate readings. It's also important to position your body correctly to ensure that you're applying the force in a straight line.

When using electronic torque sensors, it's important to ensure that the sensor is properly aligned and that the load is applied evenly. Misalignment can cause inaccurate readings, and uneven loading can damage the sensor. This is especially true when measuring dynamic torque, where the load can change rapidly.

Ultimately, practice makes perfect. The more you use torque measuring tools, the better you'll become at applying the correct technique and obtaining accurate readings. So, get out there and start twisting! Just be sure to practice on something that won't break if you over-tighten it!

Real-World Applications of Torque Measurement

Torque measurement isn't just an academic exercise; it has numerous practical applications in various industries. Let's explore some real-world examples to see how torque measurement is used in action.

7. Automotive Industry

In the automotive industry, torque measurement is critical for designing and testing engines, transmissions, and other components. Engine torque is a key performance indicator, and accurate torque measurement is essential for optimizing engine performance and fuel efficiency. Ever wonder why your car has that "get-up-and-go"? That's torque at work!

Torque measurement is also used to ensure that fasteners are tightened to the correct specifications. Over-tightening fasteners can damage components, while under-tightening fasteners can lead to failures. Torque wrenches are used on the assembly line to ensure that all fasteners are properly tightened.

Furthermore, torque measurement plays a crucial role in vehicle testing. Torque sensors are used to measure the torque applied to the wheels, steering system, and other components during vehicle testing. This data is used to evaluate the vehicle's performance and identify potential problems.

From designing high-performance engines to ensuring the safety of everyday vehicles, torque measurement is an essential tool in the automotive industry. It's the unsung hero that keeps our cars running smoothly and safely.

8. Aerospace Industry

In the aerospace industry, torque measurement is even more critical due to the extreme conditions and high stakes involved. Accurate torque measurement is essential for ensuring the safety and reliability of aircraft components. Imagine the consequences of a bolt coming loose mid-flight!

Torque measurement is used to tighten fasteners on aircraft engines, wings, and other critical components. Torque wrenches are used to ensure that all fasteners are tightened to the correct specifications, and electronic torque sensors are used to monitor the torque applied to rotating components.

Torque measurement is also used in the testing of aircraft components. Torque sensors are used to measure the torque applied to the landing gear, control surfaces, and other components during testing. This data is used to evaluate the component's performance and identify potential weaknesses.

From the smallest bolt to the largest engine, torque measurement plays a vital role in ensuring the safety and reliability of aircraft. It's a critical part of the aerospace industry's commitment to safety.

How To Calculate Torque Wrench Extension YouTube

FAQ

Alright, let's tackle some frequently asked questions about torque measurement. Because, let's face it, this stuff can get a little confusing!

9. Q

10. A

11. Q

12. A

13. Q

14. A